My Job

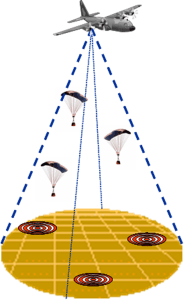

Because basically everything I worked on at Morse fell under ITAR, I unfortunately need to be very general in how I describe my work. While at Morse, I designed and built multiple electro-mechanical systems designed to survive extremely low temperatures and repeated hard impacts with the ground and developed payload release system for reliable release of roughly 60lbs.

Outtakes/Results

I developed a self-righting, redundant GPS/barometer miniature payload under 150g to survive impacts of about 20ft/s into concrete using thermoformed plastics.

I also designed a multi-camera system to continuously record several key areas of interest on a UAS while surviving extremely low temperatures and several impacts into the ground.

Towards the end of my co-op I also designed a payload release mechanism to reliably release 60lbs off of a very large consumer octocopter using a OTS quick release hook used for kite surfing and a hobbyist 9g servo.

I also designed several other systems throughout my time, but I can’t talk quite so in depth about them.

All of the systems I talked about above got tested in the field on two different flight test campaigns that totaled slightly over 3 weeks. Throughout these flight test campaigns I was part of every phase of preparation, execution, recovery, and field repairs of the systems tested, beyond just the ones that I designed. Off all the systems that I designed throughout all the flights, there was only one failure caused by a faulty battery.

Over the course of the 6 months, I designed and tested, both in lab and in the field, a multi-camera system to continuously record several key areas of interest on a UAS while surviving extremely low temperatures and several impacts into the ground. For the field tests, there were two flight test campaigns of a little over 3 weeks in total. One of the issues I noted after the first flight test is each camera system recorded to a different SD card, and the files were limited to 5 GB. So, on an hours long flight test there could be 5 different video files that needed to be spliced together into one rather massive video file. One the first, slightly shorter flight test, this required a lot of man-hours. So,

More Details

Multi-Camera System

- Each camera (6 different ones) recorded to a different SD card, and the files were limited to 5 GB. So, on an hours long flight test there could be 5 different video files that needed to be spliced together into one rather massive video file for each camera.

- On the first, slightly shorter, campaign, this required a lot of time to join the video files together in iMovie one camera at a time.

- Before the second campaign, I wrote a python script using the FFMPEG command line tool and the multithreading library to merge all the videos automatically and simultaneously for all cameras. On the second flight test campaign, this script saved about 2 man-hours and 6 hours of computer processing time for each flight test.